There are two primary reasons to prioritize the management of compressed air:

1. Air Quality: The quality of compressed air is crucial in any production line. Contaminants in the air can compromise product integrity, reduce efficiency, and lead to equipment malfunctions or failures.

2. Leakage and Energy Loss: Air leaks can cause considerable energy losses, leading to high financial costs for companies. Identifying and preventing these leaks is crucial for maintaining operational efficiency and controlling expenses.

Air is Energy (Air Saving = Energy Saving)

Janatics offers a wide range of products that can measure air consumption. Our software application provides comprehensive data and analysis for these measurements.

Air Monitoring System Products

Mini

Compact

Thread Type

Thread Type Individual Machines Service able Both cumulative & Current consumption display

View MoreUniversal

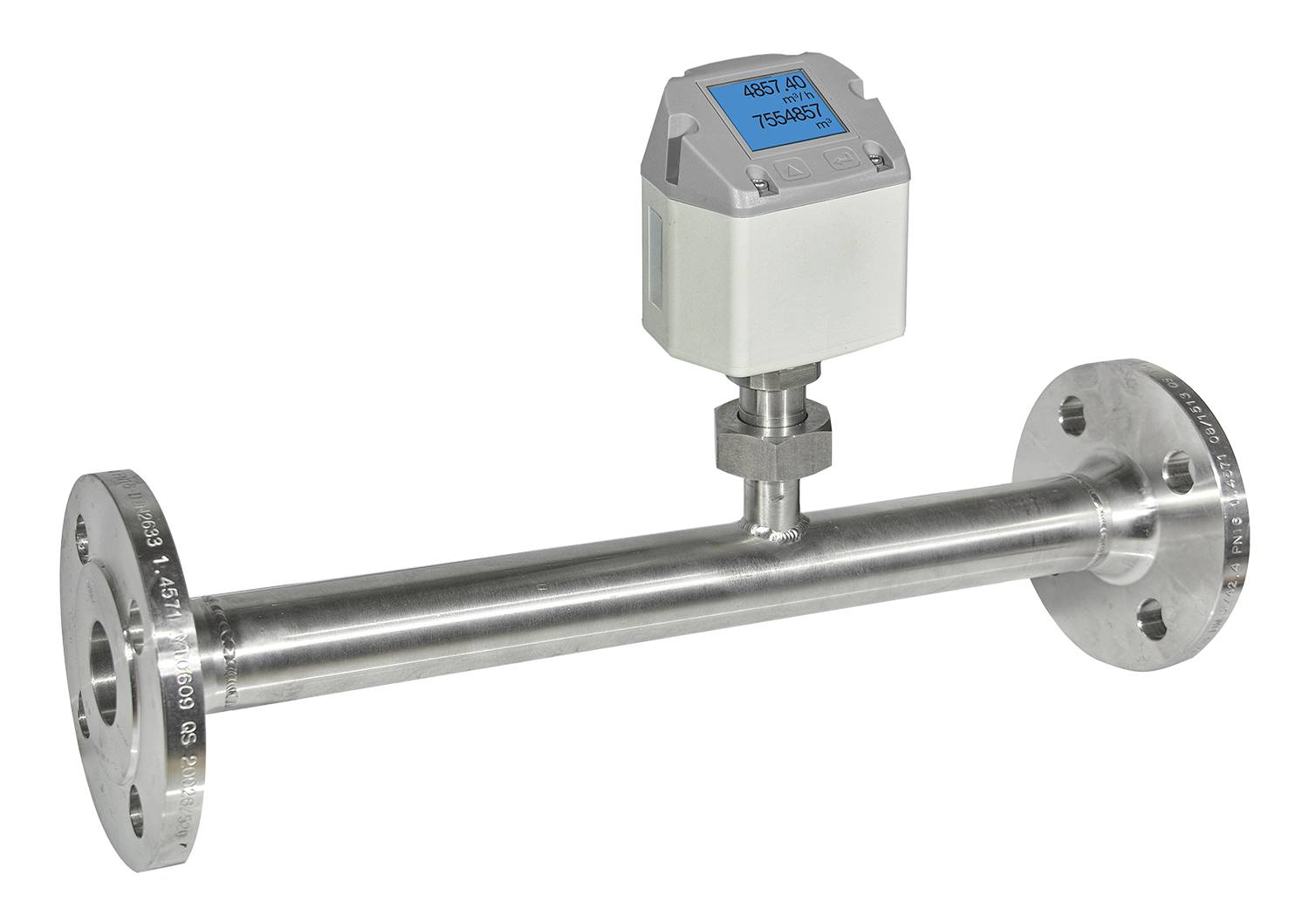

Flange Type

Flange Type Department lines Can be used from DN 8 to DN 80 For velocities up to 224 Nm/s

View MoreUniversal

Insertion Type

Inserion Type Compressor outlets Applicable from 1/2” to 12” Easy installation under pressure

View MoreEnergy Audit Solutions

Capture & Analysis

Air consumption Data acquisition

from individual machines

Comparison of recommended

vs actual consumption

Identification of machines with air leakages at OFF condition

Identification

Detecting leakages during operation with highly sensitive ultrasonic detectors

Photographic documentation

Identifying and classifying leakages according to priority

Solution for Leakage

Replacement of faulty parts

Tubing / Fittings / cylinders / valves

Sealing or replacement of seals

Online Monitoring System

Continuous compressed air monitoring with flow meters reduces the risk of production downtime due to an unplanned system shutdown. Even the smallest changes in volume flow point to potential weak points in a compressed air network, so maintenance work can be performed in good time, before this results in greater damage to machines and systems

Advantages:

Real time data for analysis

Monitor, optimize and to control the system

Reduce Maintenance costs

Applications

All industries using compressed air in their production line

Product Based Enquiry ?